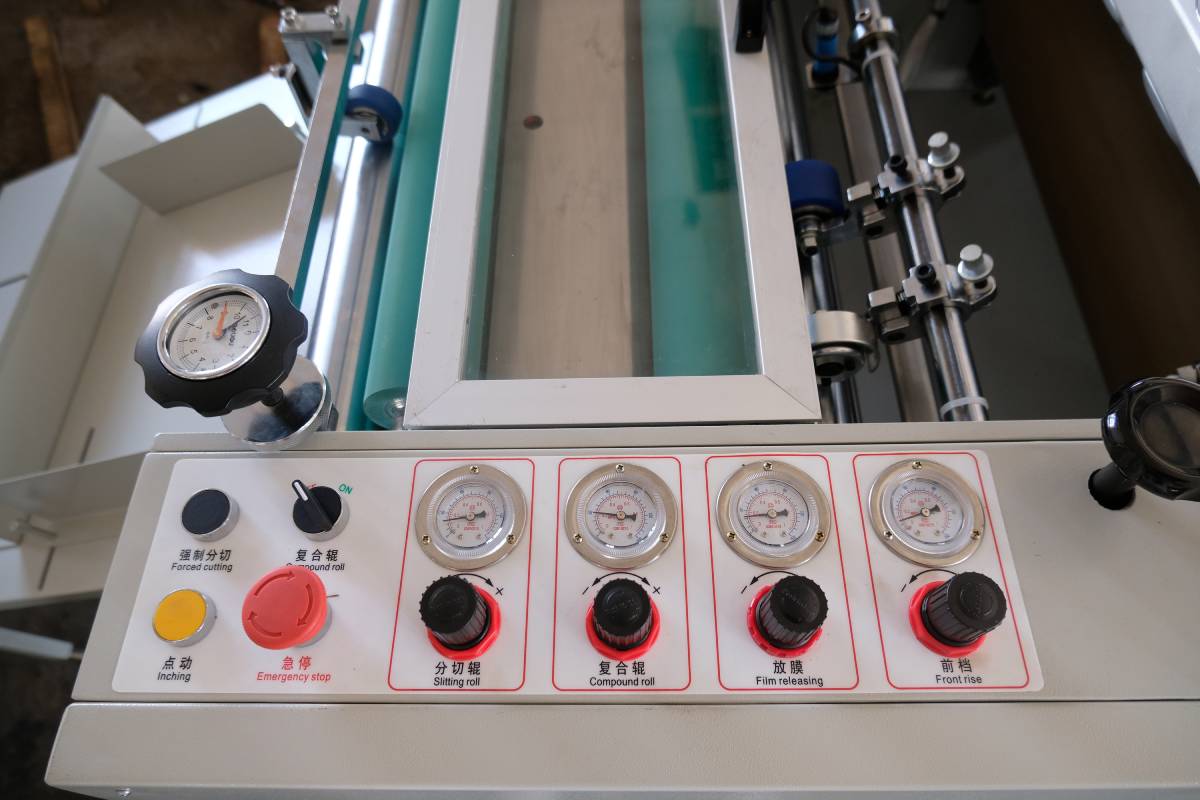

laminating machine——SWFM-560C

What are the machine parameters of the machine?

The mode is SWFM-560C. It's a heavy-duty computer-controlled laminating machine with an auto cut. The machine parameters are as follows. The max paper size is 560mm. Furthermore, the operating speed is 0-20m/min. Moreover, the laminating temperature is 30~160℃ and the total power is 10kw. Lastly, the dimensions(L×W×H) are 2.7×1.44×1.4m.

How does the film work after it's laminated?

Lamination is a commonly used post-press finishing method for printed materials such as books and periodicals. It has a wide range of applications and is also suitable for digitally printed products.

The plastic films commonly used in laminating machines are polyvinyl chloride (PVC), polypropylene (BOPP), and polyester (PET) films. Among them, BOPP film (3-8 pm) is flexible, non-toxic, high in transparency, and cheap, and is an ideal composite material in the lamination process.

According to the performance and purpose of the film itself, the thickness of the film should be between 0.01-0.02mm. It must be treated by corona or other methods. The surface tension of the treated surface should reach 4Pa, to have better wetness and adhesion. The corona-treated surface should be uniform and the transparency should be as high as possible to ensure that the covered printed matter has excellent clarity. The transmittance of PET is generally 88-90%, and the transmittance of several other films is usually between 92-93%. The film needs to have good light resistance, not easy to change color under long-term exposure to light, and have stable geometric dimensions.

Since the film is in contact with solvents, adhesives, inks, etc., it must have certain chemical stability. The appearance of the film surface should be smooth, without unevenness and wrinkles, and the film is also required to be free of bubbles, shrinkage holes, pinholes, and pitting. Due to the limited adjustment ability of the laminating machine, it is also required that the rewinding is neat and the two sides are tight to ensure uniform coating. Of course, the cost is lower.

What is the function of lamination?

Laminating the surface of digital prints, especially after printing a large area of solid, will help protect the prints in post-press processing, especially when cutting or packaging, and enable printing. The product is more beautiful and durable. However, single-sided lamination of double-sided prints is not necessarily beneficial, because the uncoated side may easily peel off the printing color due to friction in the subsequent processing. Many printed products are covered with various bright films, matt films, and matte films on the surface to pursue distinctive effects. However, it is more suitable to use thermal lamination for digitally printed prints, which is easy to use and inexpensive.

What does the laminating machine do to our lamination industry?

The laminating machine is a device that peels off the roll of protective film release paper from the backing paper, and then laminating on the product as required. It is one of the indispensable components of modern packaging. In the past ten years, people have paid more and more attention to the pursuit of healthy nature. The quality of packaging also has more stringent requirements, which promotes the continuous improvement of the technical level of laminating machines, and there are more and more types of laminating machines on the market to meet various market demands. And from the initial manual and semi-automatic lamination to fully automatic high-speed lamination, it is widely used in printing, hardware, plastic, electronics, toys, food, daily chemicals, medicine, and other industries.

At present, there are many types of laminating machines on the market, which can meet the different product needs of all walks of life. Among them, the automatic laminating machine has the characteristics of small size, wide application range, high production efficiency, good stability, and long service life, and plays an important role in the packaging process of various industries.

Nowadays, many companies want to improve production efficiency and reduce production costs while pursuing product quality, thereby reducing product prices and improving product competitiveness. The improvement of quality and efficiency also requires efforts in packaging. The automatic laminating machine can perfectly help enterprises to achieve these two needs so that users' products can be more perfectly presented to customers.

What are the factors that depend on the quality of laminating machine?

With the development of the economy and technology, various industries such as printing, hardware, plastics, electronics, toys, food, daily chemicals, medicine, etc. are also developing continuously. It is difficult for traditional equipment to meet the current demand, such as the mobile phone industry. , factory environment, user needs, and other aspects are different, which requires the automatic laminating machine upgrade and innovation to keep pace with the times and to meet the needs of the current era at different stages.

The quality of the laminator

1. Work efficiency, whether the automatic laminating machine we purchased can replace its manual and efficient completion of product attachment work, if not, don't think about such a machine, after all, one of the purposes of purchasing an automatic laminating machine is to hope The automatic laminating machine can help us to complete the product attachment work efficiently and with high quality.

2. The stability of work, this goal is quite important. Production-oriented enterprises must have output value every day to make profits. Or strikes and other phenomena will inevitably affect the normal work of our entire production, so the stability of the equipment determines the efficiency of the entire production.

What is the influence of a fully automatic laminating machine on the lamination industry?

The automatic laminating machine has a pivotal position and effect in the packaging industry, providing the industry with the necessary technical equipment to complete the packaging process of the product. Although the output of packaging machinery is not as large as packaging materials in the entire packaging industry and is not a regular consumable, it is an indispensable support for the modernization of the packaging industry. Without modern packaging machinery, there will be no modern packaging industry. Packaging machinery is a large category of products in the packaging industry. Packaging machinery used to complete the packaging process can be divided into 11 categories, filling machinery, filling machinery, sealing machinery, wrapping machinery, multi-purpose packaging machinery, labeling machinery, cleaning machinery, drying machinery, sterilization machinery, strapping machinery, and collection machinery. Packing machinery, auxiliary packaging machinery, equipment, etc. As a professional machine, in addition to the general requirements of ordinary machinery, packaging machinery also has the requirements of a beautiful surface, compact transmission, stable operation, high precision, and high production efficiency, to fulfill its function well and meet the market demand.

What is the development trend of the fully automatic laminating machine?

Nowadays, with the continuous improvement of living standards, people's requirements for products are getting higher and higher, and the workmanship and packaging of products also need to be more and more refined. The laminating machine equipment has been difficult to meet the needs of enterprises for automation, and the humanized automatic laminating machine has entered a new stage of development.

The humanization of the automatic laminating machine is mainly reflected in the following three aspects:

1. Visual human nature: This is reflected in the exquisite appearance of the device, just like a mobile phone, the humanized automatic laminating machine is not only efficient but also beautiful and has eye-catching functions.

2. Functional safety: The humanized automatic film machine fully considers possible risk factors, and takes preventive measures to prevent personal injury.

3. Expansion function: The humanized automatic laminating machine is not static, and the expansion module can be increased with the increase in the degree of automation, which can meet the needs of various applications.

Humanized lamination brings more opportunities and simplicity to the development of automatic laminating machines. It is believed that in the subsequent development process, its application will become more and more extensive, and the humanized identification method will be realized in enterprises, and it will also promote The development of the social economy is of great significance to the entire laminating machine equipment industry. In the entire development process of the laminating machine, foreign advanced technology and domestic traditional technology are integrated to develop laminating machine equipment suitable for customers. Both domestic and foreign markets have strong competitiveness.

What are the precautions when using a fully automatic laminating machine?

1. The use environment of the equipment

1. It is required to be indoors, and it is not easy to use it in a high temperature, humidity, acid, and alkaline environment, so as not to affect the service life, efficiency, and accuracy of the equipment.

2. Keep it clean

1. After use, the mechanism of the equipment, such as friction rollers, electrical boxes, etc., should be cleaned up. Cleaning and maintenance can be performed with alcohol or a commercial neutral cleaning solution.

Three, cleaning needs attention:

1. Do not use cleaning tools that damage the mechanical surface.

2. Do not use corrosive plastic utensils.

3. Do not use acid solution.

Fourth, regular inspection and maintenance:

1. Periodic inspection of the machine should be carried out to maintain the normal operation of the machine, including but not limited to the following aspects.

2. Clean up discarded paper scraps and debris.

3. Remove the oil residue from the rollers and edges.

4. Use a soft brush or cloth to clean the sensor lens.

5. Regularly replace the fuse. This device uses AC power, and a fuse should be used to prevent overload.

6. Try not to put the product in when the device is turned on, and then put the product after the device is turned on normally. Because the acceleration of the machine equipment is relatively large at the moment of starting, the load is easy to cause vibration, and the excessive load to the screw will affect its life.

7. Anti-rust, use anti-rust oil to spray all stainless steel and iron parts and gently wipe with a soft cloth.

8. During the operation of the machine, it is strictly forbidden for water droplets to fall on the machine to prevent the machine from rusting and causing the danger of electric shock.

The automatic laminating machine should pay attention to maintenance, it will be more durable!

What are the maintenance measures of the fully automatic laminating machine?

Most industries need to use automatic labeling machines during production. Through the use of this equipment, work efficiency can be improved and the competitiveness of enterprises can be effectively improved. In the daily use process, it is necessary to clarify the relevant maintenance skills, especially in the lubrication process, you need to pay attention to the relevant matters.

During maintenance, cleaning should be done well. The main reason is that the labeling machine is easy to enter dust during operation, so it is necessary to regularly clean the dust on the labeling machine. If you do not use it temporarily, you should unplug the power supply at this time and cover it with a dust cloth to effectively prevent dust from falling on the labeling machine.

In the process of regular decontamination, it is necessary to treat the high-temperature belt, only in this way can better ensure the high-quality operation of the self-adhesive labeling machine. Moreover, many parts are prone to rust and wear after using for some time. At this time, lubricating oil needs to be used to ensure that each part is smooth. After the equipment has been running for some time, it should be regularly maintained to ensure good operation and prolong the service life of the equipment.