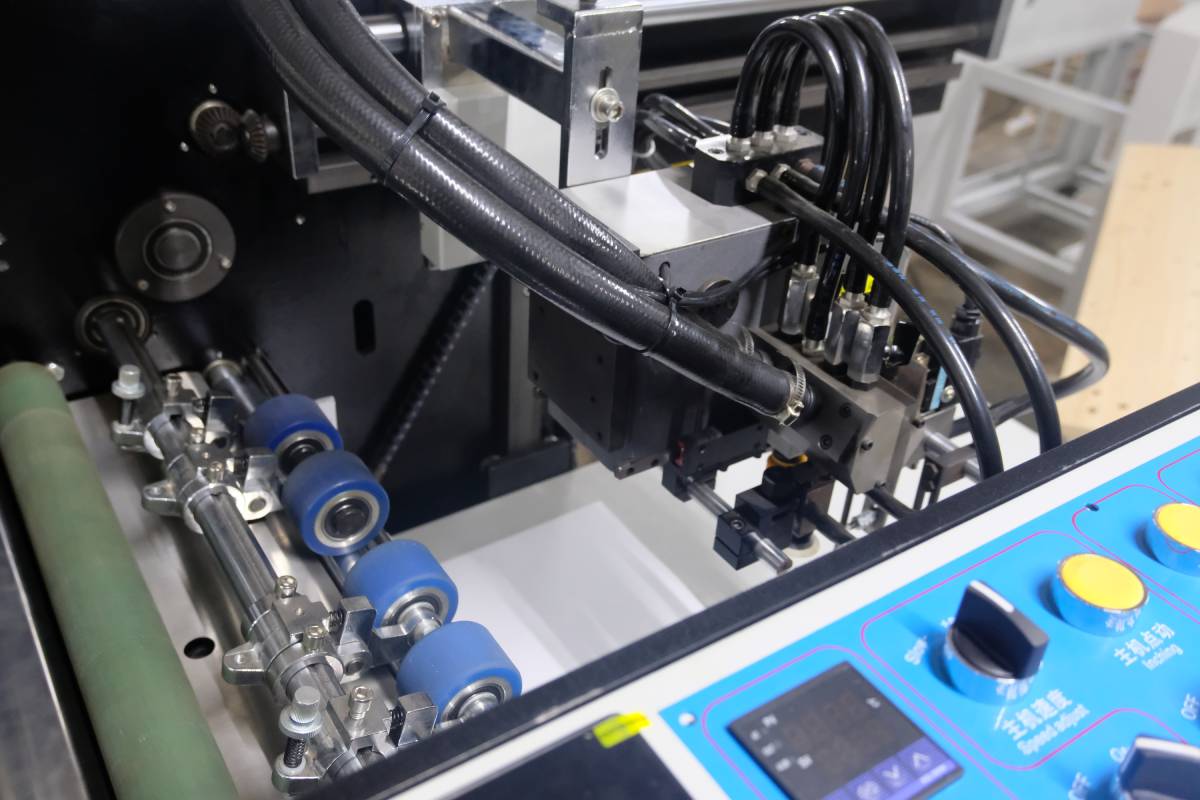

laminating machine——SWFM-540

Why do we choose to laminating machines?

With time, my country's economic level is constantly improving, and the comprehensive national strength is also gradually increasing. This has also promoted the continuous improvement of people's living standards in our country. People no longer only pay attention to food and clothing. People's consumption level and consumption concept are also constantly improving along with the strength of the country, which also drives the corresponding The production of many industries has forced them to expand the scale of production and improve production efficiency. In particular, the development of the food industry, daily chemicals, medicine, and other industries that are closely related to the people's livelihood industry has to improve the performance requirements of the laminating machine, again and again, to keep up with the market changes. The laminating machine can no longer meet the production needs of some large enterprises, so the introduction of new laminating machines is imperative for large enterprises.

The choice of a laminating machine is not only to save the company's funds, but more importantly, it can save a lot of labor, and can also achieve high-quality and high-efficiency production, to achieve the company's high-efficiency and low-consumption production goals. At present, the application scope of the laminating machine on the market is still very limited, mainly because the traditional laminating machine system has many shortcomings, such as the large equipment, the difficulty of re-installation, and the high maintenance cost, and the high sales interest. The problems are all hindering the future development of the laminating machine. Therefore, after the laminating machine has undergone a gorgeous transformation, it can completely solve the stumbling block on this development path.

What are the machine parameters of the machine?

The mode is SWFM-540. It's a fully-auto laminating machine with an auto cut. The machine parameters will be as follows. The max paper size is 540*780mm and the min paper size is 210*290mm. Furthermore, the paper thickness is 105-500g. Moreover, the max speeding speed is 0-30m/min and the gross power is 15/8kw. The total weight is 1400kg. Lastly, the overall dimensions(L×W×H) are 3200*1250*1650mm

What is the difference between oil heating and electronic heating?

During the lamination process, we will encounter some full-color colors. The full-color color means that the entire layout is red, or the entire color is black. The temperature of the machine without oil heating is uneven. , say 100 degrees in one place and 80 degrees in another. The roller is a face if the roller is 100 degrees on one side, 80 degrees on the other, and 70 degrees on the other. If 100 degrees just meet the brightness requirements, then 80 degrees will not meet the requirements. There will be snowflakes on the film, and snowflakes are white spots. Oil heating is to add oil to the roller, heat the oil, and the oil will rotate 360 degrees on the roller. Then the temperature on the roller will be relatively uniform, and the temperature difference between different positions is less than 1 degree. This will achieve a full-color effect. Among the lamination, black, blue, red, and green are the most difficult to coat. Generally, other people's machines cannot carry out the lamination of these four colors. As soon as the film covered is torn off, or large white spots appear. He had two reasons, firstly it didn't have enough pressure and secondly, it wasn't an oil-heated machine. All electrically heated machines are not very fast. The main reason is that it cannot maintain a constant temperature. The temperature of the electric heating machine relies on the heat emitted by the lamp to heat the roller. During the operation of the machine, the temperature of the roller will change greatly. Once it is lowered too much, it will affect the effect of the coating. At this time, it is necessary to wait for the temperature to rise to the required temperature before it can continue to work, which will lead to a decrease in the efficiency of the coating. The oil-heated roller keeps heating the oil during the working process, which can ensure that the temperature is relatively constant and does not change much, thereby improving the work efficiency. This is the difference between oil heating and electric heating.

What are the advantages of the fully-auto laminating machine?

1. High efficiency and low cost. The automatic laminating machine is a modern mechatronics product, which fundamentally changes the situation that manual lamination is inefficient and the quality of lamination is not high. The use of laminating machinery not only packs the production output but also greatly reduces the input cost and increases the production vitality of the manufacturer.

2. High performance and higher cost performance. The automatic film laminating machine can not only meet the work needs of the above industries but also has a long service life in addition to the remarkable characteristics of fast lamination speed and high precision. The general service life of a laminating machine is about 8-10 years. Taking the price of the mainstream laminating machine now, the market price of a semi-automatic high-precision laminating machine (standard machine) is generally 30,000 to 50,000, and the average annual investment is 30,000 to 5,000. The film production can be completed, which is equivalent to one month's labor cost. It can be seen that the laminating machine is very cost-effective.

3. Wide range of applications and diverse uses. Automatic filming machinery meets the needs of filming in all walks of life, such as mobile phones, daily chemicals, food, chemicals, medicine, plastics, electronics, hardware, cosmetics, and other industries. around the device, sticking acrylic plates, etc. The emergence of the laminating machine has made previously impossible processes such as manual lamination simple and feasible.

4. Convenient and reliable, easy to manage. With the excellent quality and reliable working performance of the laminating machine, the high-precision laminating machine has the advantages of cleanliness and hygiene, no mold on the vertical laminating machine, beautiful and smooth after lamination, and will not fall off by itself. The equipment is simple to operate. For many small and medium-sized enterprises, one or two automatic laminating machines can meet their production needs. Compared with the original need to manage several workers for lamination, laminating machines undoubtedly have excellent management and convenience.

What is the market value of a fully-auto laminating machine?

According to the current market performance of the packaging industry, the automatic laminating machine is still one of the important members of the electronics industry. With the continuous advancement of technology, the performance of the automatic laminating machine is more stable and the precision is better, and it will continue to provide new products for the electronics industry. vitality. Now the automatic laminating machine can add automatic loading and unloading mechanism, electrostatic precipitator, and FFU high-efficiency purification hood; the functions are complete, and you can mix and match. Therefore, the automatic laminating machine provides enterprises with better lamination services, thereby improving the production efficiency of enterprises and saving production costs.

No matter the type or brand of laminating machine on the market, there are more and more laminating machines like mushrooms after a spring rain, but even if some laminating machines reduce the price and increase publicity, they are still ineffective, and some laminating machines are booming even if they are expensive. What is the root of this problem? It is simply that smart merchants will improve and develop laminating machines according to the needs of consumers, but some merchants have always thought that they can rely on price to fight a protracted war.

In today's market, people's demand for commodities is increasing, and the requirements for commodities are getting higher and higher, so this will inevitably make commodity manufacturers have higher and higher requirements for the machinery they use, so the market The requirements for automatic laminating machines are gradually increasing. At this time, some merchants didn't even know it, they just immersed themselves in the production of their automatic laminating machines, ignoring the changes in the market, so the products that were produced were not interested at all. Now the market hopes to be able to achieve multi-function on one device, with higher production efficiency, and to meet the requirements of fast replacement of enterprise products and large demand. If you want to use a multi-functional application on a fully automatic laminating machine, you should adopt a modular design. Through the research and improvement of different functional modules, different modules in the new equipment can be continuously slowed down in use. So that the equipment can be adapted to different packaging materials, packaging products, and different packaging standards, to meet the packaging requirements of different customers, and also realize the multi-function of the laminating machine. Therefore, when we manufacture and produce an automatic laminating machine, we must first conduct a market survey, and then design and produce our automatic laminating machine according to the results of the survey.

What is the future development direction of laminating machines?

Today's new technology has promoted the packaging industry to a new model, and the current automatic laminating machine is the most popular packaging equipment. Because of its appearance, many companies have improved their work efficiency and brought objective benefits to various companies. The benefits of this machine and the storage of this machine are very convenient, ensuring the freshness and quality of our products.

If the equipment wants to develop lastingly and stably, it must not only keep up with the trend of market development, abandon outdated ideas, use high technology to improve the technical level, and improve performance and quality, but also formulate its development plan according to the actual situation. , so that their rational development, and long-term development. With the improvement of living standards, the automatic laminating machine can have a more stable development in the entire packaging machinery industry.

In recent years, due to the important role played by the packaging industry in the entire economic development process, the automatic laminating machine has been well developed as indispensable equipment in the packaging industry. There are certain limitations in many aspects, and there are still deficiencies in standard level, manufacturing technology, quality, and performance. If we want to break the deadlock of this kind of war, we believe that we must develop the potential of the market and introduce advanced technologies and guarantees. As an enterprise, the most important thing is to start from the essence, so that our automatic laminating machine can start from the most fundamental The design of the equipment starts to carry out strict, comprehensive, and systematic monitoring of our products so that our equipment has its room for stability in the face of greater market competition.

People living in the current era prefer green food and pay attention to a healthy diet. Because of this, natural and fresh food is more popular, and fresh items continue to increase with people's needs. Recently, manufacturers of automatic laminating machines have improved the performance of the equipment in all aspects, so that the packaged items have a longer storage period and better freshness.

If the automatic laminating machine can play a good role in keeping items fresh, it will not only give people a good visual display but also bring more convenience to people.

How do we maintain the laminating machine?

Most industries need to use automatic laminating machines during production. Through the use of this equipment, work efficiency can be improved and the competitiveness of enterprises can be effectively improved. In the daily use process, it is necessary to clarify the relevant maintenance skills, especially in the lubrication process, you need to pay attention to the relevant matters.

When carrying out maintenance, you should do a good job of cleaning. The main reason is that the laminating machine is easy to enter dust during operation, so it is necessary to regularly clean the dust on the laminating machine. If you do not use it temporarily, you should unplug the power supply at this time and cover it with a dust cloth to effectively prevent dust from falling on the laminating machine.

In the process of regular decontamination, it is necessary to treat the high-temperature belt, only in this way can better ensure the high-quality operation of the self-adhesive laminating machine. Moreover, many parts are prone to rust and wear after using for some time. At this time, lubricating oil needs to be used to ensure that each part is smooth. After the equipment has been running for some time, it should be regularly maintained to ensure good operation and prolong the service life of the equipment.